Maintenance & testing of operating equipment - simple, safe, legally compliant

Are you responsible for the safe operation of your work equipment? Then you know: Regulations, inspection intervals and documentation requirements can quickly become confusing. With SIMPL, you can organize inspections digitally, keep an eye on all deadlines and ensure full compliance – without any Excel chaos.

This turns duty into routine – and control into a real competitive advantage.

Lack of transparency and confusing processes

Many companies do not have a central overview of their operating resources – be it machines, vehicles or ladders. Important information is often scattered around, whether in Excel spreadsheets, paper documents or in the ERP system. This leads to uncertain responsibilities and overlooked deadlines – which in the worst case can result in fines.

- No central overview of the available operating resources

- Time-consuming search for information on past or upcoming inspections

- Scattered data in different systems and formats (Excel, paper, ERP)

➡ This creates unnecessary work – and it becomes risky to monitor deadlines correctly.

Central management and automated inspection processes for operating equipment

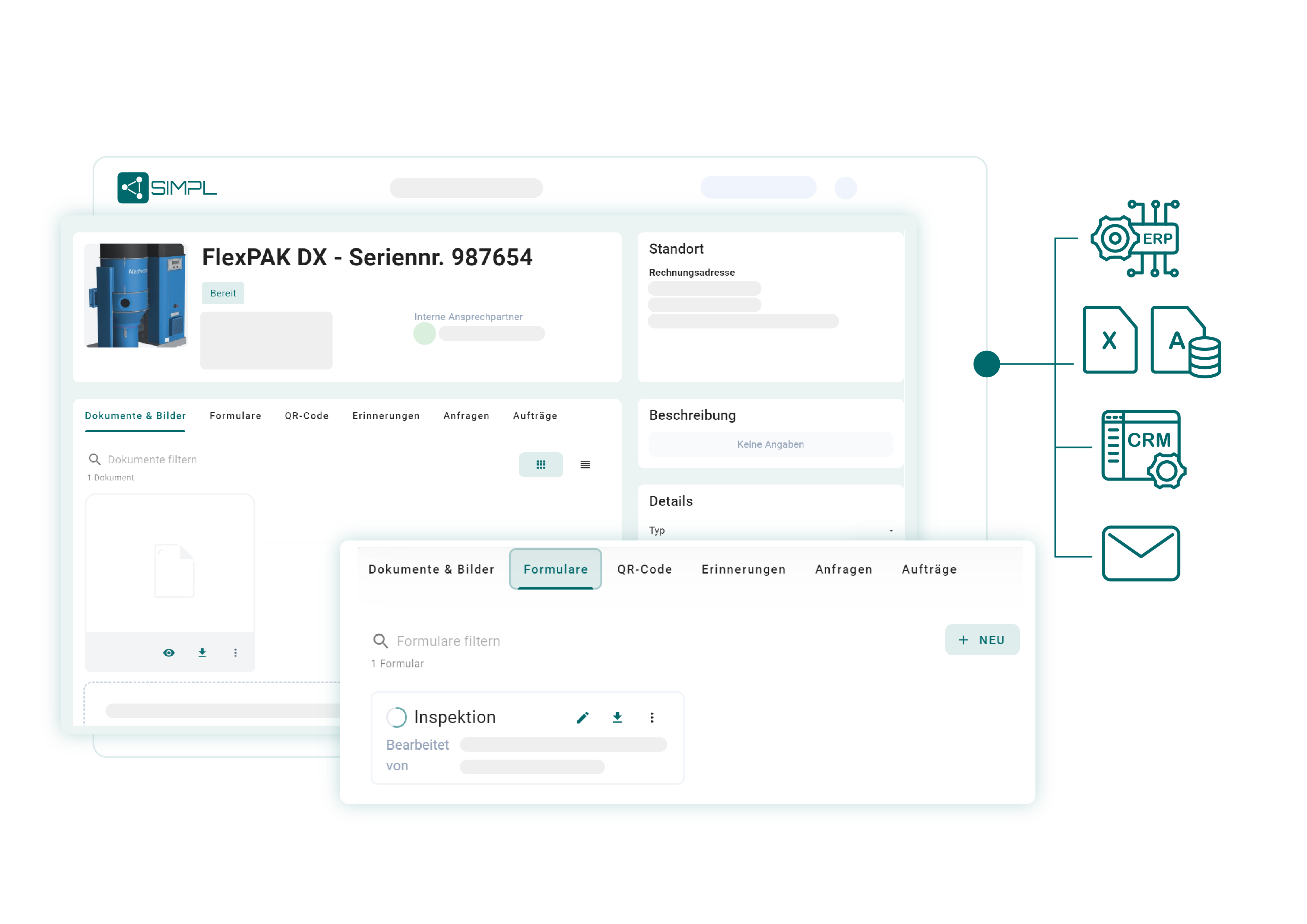

SIMPL brings structure and clarity to the management of your equipment and inspections. Our software offers a central, digital solution for all relevant information – from machines and vehicles to work equipment. Automated workflows and reminders ensure that no inspection is overlooked and all data is documented in an audit-proof manner.

- Central management of all operating resources – all information available at any time and in one place

- Automated deadline & inspection management – reminders and smart workflows ensure timely inspections

- Simple documentation & tracking – inspection logs, responsibilities and histories available in a structured manner at any time

➡ This allows you to keep an overview at all times and avoid fines for missed tests.

“ Since the introduction of SIMPL, we have systematically recorded our machines and equipment in the field of heat treatment technology. As a result, we now have complete transparency over our entire installed base, including the life cycle records. Customer inquiries can be made directly via the QR codes on the equipment, and the tedious task of printing manuals is finally a thing of the past.”

Ralf BistritzProkurist bei WELDOTHERM Gesellschaft für Wärmetechnik m.b.H.

100 % transparency across all operating resources

Ensure maximum insight into your existing equipment – from machines and vehicles to ladders and tools. This means you always have an overview of upcoming inspections, maintenance histories and responsibilities. This helps you to avoid missed deadlines, increase operational safety and reduce administrative work.

Centralized management of operating resources - always maintain an overview

With SIMPL, you can bundle all relevant information about your equipment in one place.

Whether it’s equipment data, inspection intervals or legal requirements – you have everything at a glance to ensure that your processes run smoothly and in accordance with regulations.

- All data in one place – equipment information, inspection intervals and legal requirements available at any time

- Simple planning & tracking – automatic reminders and digital inspection reports ensure a structured process

- Fast decision-making – identify bottlenecks at an early stage and manage efficiently with a transparent overview

➡ This ensures that all regulations are adhered to – and minimizes downtime.

Equipment history - complete overview for maintenance & testing

Access to past data is crucial in the maintenance and testing of equipment. With SIMPL, you can create a complete history for every piece of equipment – be it a machine, a vehicle or a ladder.

All inspection logs, maintenance measures and responsibilities are centrally linked and can be accessed at any time.

- Complete equipment history – including all past inspections and maintenance measures

- Transparency of all equipment to be inspected – everything in the system at a glance

- Simple linking between vehicles, tools and other assets

➡ This allows you to keep an overview and ensure that no important maintenance measures are overlooked.

QR codes for your operating resources - fast, digital access

QR codes offer a simple and effective way to reduce administrative work and speed up access to important equipment information. With SIMPL, you can generate QR codes for all your operating resources to make processes more efficient.

- Quick access to relevant data – scan the QR code and immediately receive all information on inspections, maintenance history and documentation

- Simple damage report – record defects or maintenance requirements directly via QR code and report them to the responsible team

- Digital equipment management – reduce paper chaos and ensure that your data is always up-to-date and stored centrally

➡ This makes the management of your operating resources efficient, transparent and always up-to-date.

Manage your operating resources easily and centrally with SIMPL

Non-binding consultation with our experts ✔

Individual insights into your resource management ✔

Efficient service growth with SIMPL ✔

Individual support from real contacts

We accompany you personally – with support that understands your industry. No call center, no script – just fast, direct help from people who really know SIMPL.

Intuitively developed for use on site

SIMPL also works where speed is of the essence: mobile, offline-capable, without long training periods. Your technicians will get to grips with it straight away – whether using a tablet or smartphone.

Made & hosted in Germany

Our servers are located exclusively in Germany, are ISO 27001-certified and GDPR-compliant. Do your customers demand confidentiality? We provide it as standard.